Thermo Form Plastic

Thermo Form Plastic - Web this guide delves into six key materials used in thermoforming: Plastic thermoforming is a manufacturing process used to create plastic parts and products. Web thermoforming, at its core, is a dynamic plastic manufacturing process driven by heat and pressure or vacuum to. Web thermoforming is a widely employed manufacturing process used to shape sheet thermoplastic materials to. Web thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific. After coming in contact with the mold, the shapes are then cut, inspected, and assembled into packaging.

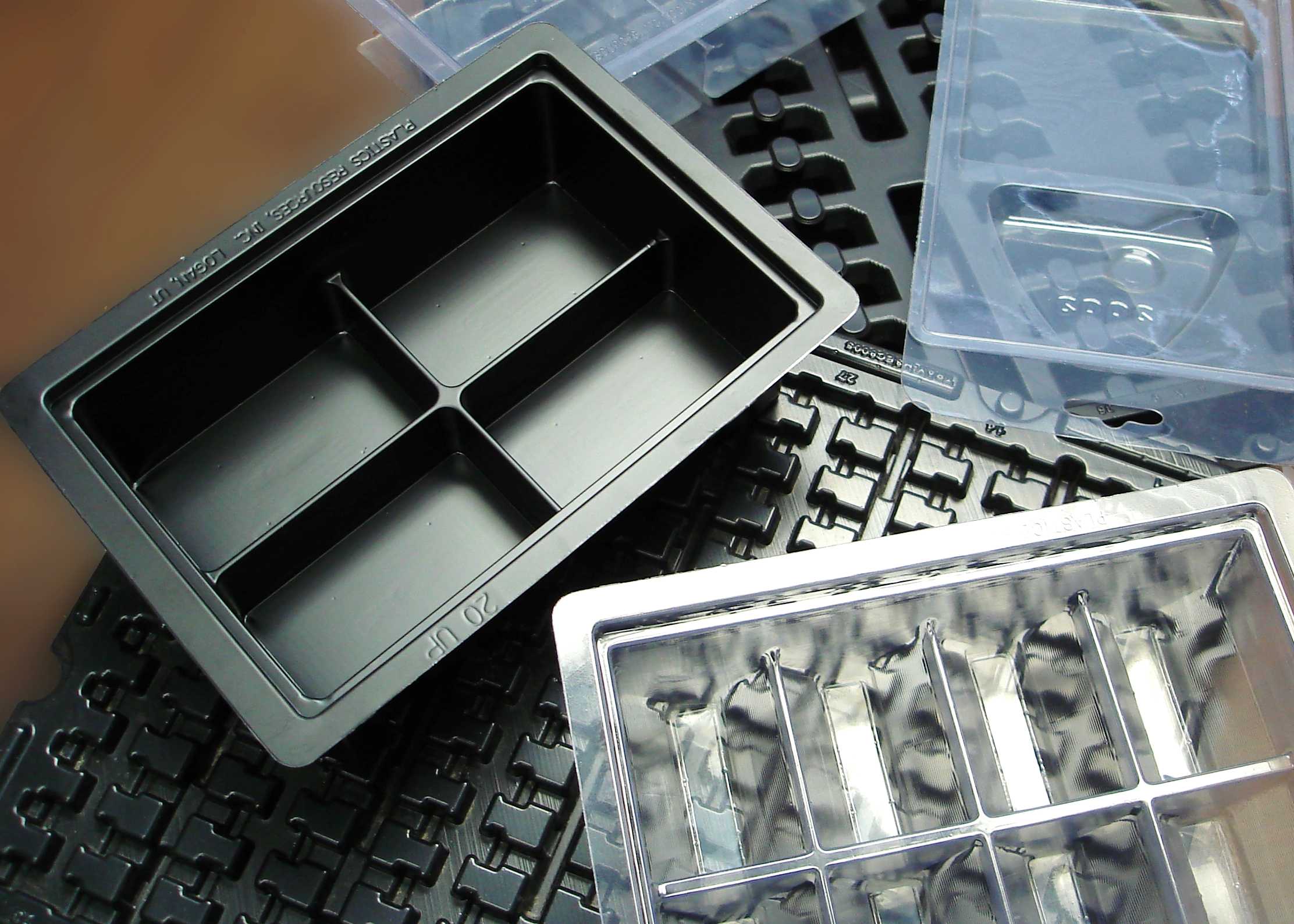

Understanding Thermoforming Plastics Resources Inc.

Plastic thermoforming is a manufacturing process used to create plastic parts and products. After coming in contact with the mold, the shapes are then cut, inspected, and assembled into packaging. Web thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific. Web this guide delves into six key materials used.

Process of Thermoforming Plastics Plastic Forming and Manufacturing Process Techniques YouTube

Plastic thermoforming is a manufacturing process used to create plastic parts and products. Web thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific. Web thermoforming is a widely employed manufacturing process used to shape sheet thermoplastic materials to. Web thermoforming, at its core, is a dynamic plastic manufacturing process.

Thermoforming · Min Plastics & Supply, Inc.

Web thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific. Web this guide delves into six key materials used in thermoforming: After coming in contact with the mold, the shapes are then cut, inspected, and assembled into packaging. Web thermoforming, at its core, is a dynamic plastic manufacturing process.

What is Thermoforming? Plastic Thermoforming Explained Productive Plastics

Plastic thermoforming is a manufacturing process used to create plastic parts and products. After coming in contact with the mold, the shapes are then cut, inspected, and assembled into packaging. Web thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific. Web this guide delves into six key materials used.

Thermoformed Plastic Trays Universal Plastics Universal Plastics

Web thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific. After coming in contact with the mold, the shapes are then cut, inspected, and assembled into packaging. Web thermoforming, at its core, is a dynamic plastic manufacturing process driven by heat and pressure or vacuum to. Plastic thermoforming is.

Thermoforming Products Plastics Unlimited

Web this guide delves into six key materials used in thermoforming: Web thermoforming is a widely employed manufacturing process used to shape sheet thermoplastic materials to. Web thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific. Plastic thermoforming is a manufacturing process used to create plastic parts and products..

Thermoform Plastic Packaging REXPLAST Industrial Plastic Food Packaging Solutions

Web this guide delves into six key materials used in thermoforming: Web thermoforming is a widely employed manufacturing process used to shape sheet thermoplastic materials to. Web thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific. Web thermoforming, at its core, is a dynamic plastic manufacturing process driven by.

FAQs Plastics Thermoforming

Web thermoforming, at its core, is a dynamic plastic manufacturing process driven by heat and pressure or vacuum to. Web thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific. After coming in contact with the mold, the shapes are then cut, inspected, and assembled into packaging. Web this guide.

Thermoforming Progard Plastics

After coming in contact with the mold, the shapes are then cut, inspected, and assembled into packaging. Web thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific. Web this guide delves into six key materials used in thermoforming: Web thermoforming is a widely employed manufacturing process used to shape.

Thermoforming Packaging Explained (How it Really Works) CPS

Web thermoforming is a widely employed manufacturing process used to shape sheet thermoplastic materials to. Web thermoforming, at its core, is a dynamic plastic manufacturing process driven by heat and pressure or vacuum to. After coming in contact with the mold, the shapes are then cut, inspected, and assembled into packaging. Plastic thermoforming is a manufacturing process used to create.

Web thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific. Web this guide delves into six key materials used in thermoforming: Web thermoforming, at its core, is a dynamic plastic manufacturing process driven by heat and pressure or vacuum to. Plastic thermoforming is a manufacturing process used to create plastic parts and products. Web thermoforming is a widely employed manufacturing process used to shape sheet thermoplastic materials to. After coming in contact with the mold, the shapes are then cut, inspected, and assembled into packaging.

Plastic Thermoforming Is A Manufacturing Process Used To Create Plastic Parts And Products.

Web thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it using a mold to specific. Web thermoforming is a widely employed manufacturing process used to shape sheet thermoplastic materials to. Web this guide delves into six key materials used in thermoforming: After coming in contact with the mold, the shapes are then cut, inspected, and assembled into packaging.